Questions during consultation

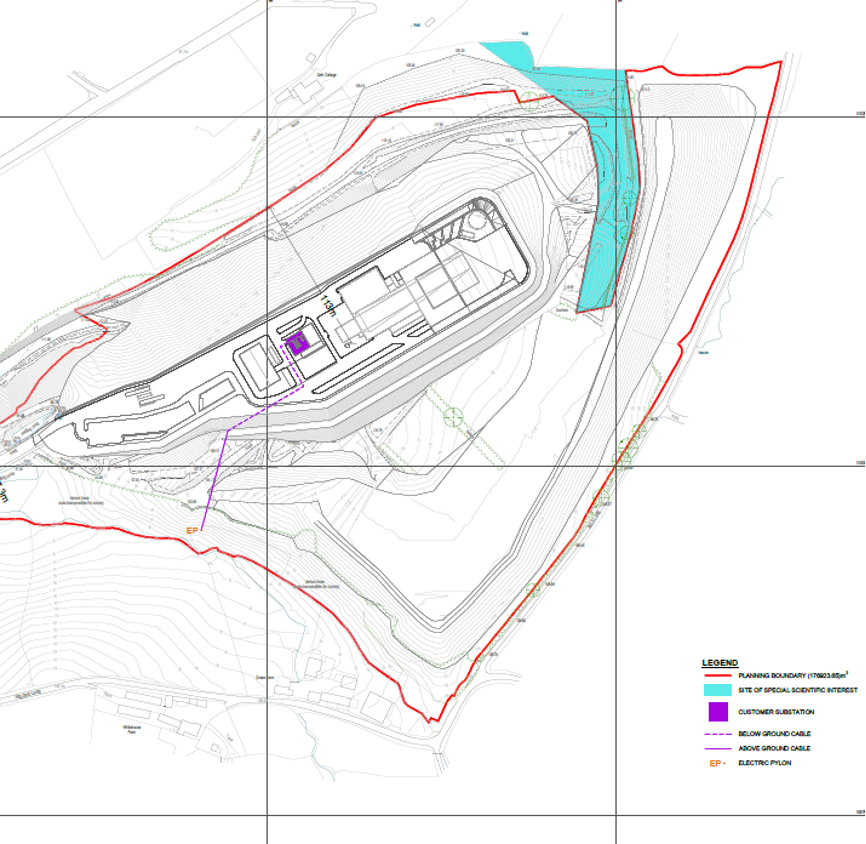

A new connection to the local electricity network would be required to export electricity off site. The substation will be located within the Installation boundary, from where cabling will run underground to the base of the quarry void (circa 104m in length), prior to overhead cable (circa 74m in length) to the existing electricity pylon as shown on the drawing below. The substation is shown as the purple block. Underground cabling is the dashed purple line, above ground is solid purple. The nominal voltage is 33kV.

Substations are part of the electricity supply network that enables the widespread use of electricity in homes, work places, schools etc. As shown below, the substation will be located within the quarry void, and there will be no public access. Anyone working on the apparatus will be authorised and competent. The means of connection and disconnection will be a single 33kV metered circuit breaker within the substation. There will also be an emergency trip facility that will open the circuit breaker and disconnect the connection.

The combustion chamber / boiler will be provided with two low-sulphur gas oil fired auxiliary burners. The burners are designed to ignite the waste for plant start-up following shutdown periods. The heat output of the burners ensures sufficient heating of the boiler before fuel loading and the lower burner output is sufficient for the support mode to ensure a furnace temperature of at least 850°C is maintained at all times in accordance with IED requirements.

The substation will be located within the Installation boundary, from where cabling will run underground to the base of the quarry void (circa 104m in length), prior to overhead cable (circa 74m in length) to the existing electricity pylon as shown on the drawing below. The substation is shown as the purple block. Underground cabling is the dashed purple line, above ground is solid purple. The nominal voltage is 33kV. No new pylons are proposed.

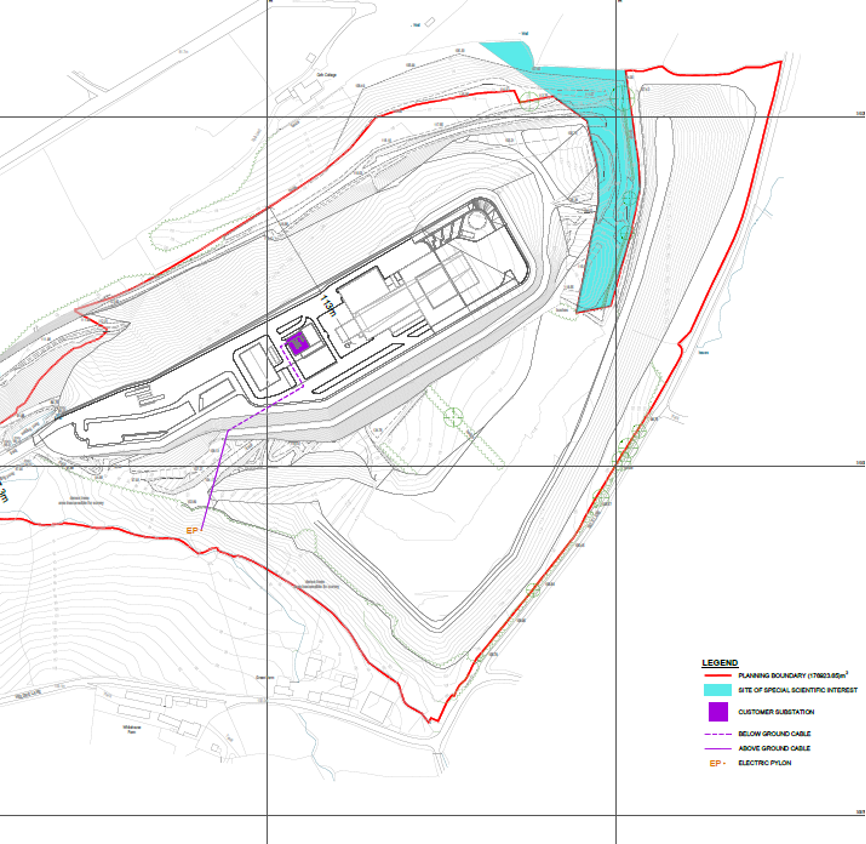

The Buttington ERF would accept deliveries of waste for up to 12 hours on weekdays and 5 hours on Saturdays. Assuming equal numbers of HGV trips during each hour, there would be an average of 4 HGV arrivals and 4 HGV departures during each hour on a typical weekday.

A summary of the expected level of HGV traffic attracted to the Buttington ERF on a typical weekday is provided below.

After weighing, authorised vehicles will be directed to one of the tipping bays in the Waste Reception Building by means of an electronic traffic light and barrier traffic management control system; each tipping bay is accessed by means of a fast action roller-shutter door which will be operated automatically on the approach of a vehicle. The roller-shutter door will close after the vehicle enters the tipping bay to ensure that all waste handling activities are undertaken within the confines of the building.

Following tipping of its waste, the tipping exit bay door will be opened and the vehicle will exit the site via the Out-Weighbridge, which is also fully automated and linked to the ANPR and site CCTV systems; this weighbridge will also be controlled via a traffic light and barrier system.

The following mitigation measures will be implemented to reduce the risk of odour or vermin and scavengers arising from the Installation’s activities:

· all waste transfer, including loading and unloading will take place within the confines of the building;

· the reception of waste from delivery vehicles will take place through automatic fast-acting doors;

· once the waste materials are inside the building, all off-loading will take place within the building;

the Installation will be equipped with a sophisticated atmosphere control system - air collected by the atmosphere control system will be used as combustion air in the combustion plant chamber;

· all elements of the atmosphere control system will be incorporated into the Installation’s planned preventative maintenance (“PPM”) system;

· housekeeping, both externally and internally, will be of a high standard; the PPM system at the Installation will incorporate procedures for housekeeping, supported by the production of housekeeping schedules; and

· daily visual and olfactory assessments will be undertaken at the Installation.

The Installation will be required to operate under an Environmental Permit that will be issued by Natural Resources Wales (NRW). All monitoring requirements will be stipulated within the permit. There will be both continuous monitoring of emissions to air and periodic monitoring of emissions to air.

All periodic monitoring will be undertaken by an organisation that is suitably United Kingdom Accreditation Service (“UKAS”) accredited and holds the necessary certifications under the EA’s MCERTS Scheme for Manual Stack Sampling. All sampling personnel will hold the appropriate personal accreditations.

Any samples collected during periodic monitoring that require off-site analysis will be sent to a laboratory that is suitably UKAS accredited for that determinand and sample matrix.

All periodic monitoring will be undertaken to the current requirements of the relevant CEN, or ISO sampling standards and the NRW Technical Guidance Note (Monitoring) M1 Monitoring of stack emissions to air.

All monitoring data will be submitted to NRW and this is published on NRW’s Public Register.

Monitoring of the soils and the underlying groundwater will be undertaken in accordance with the requirements of the Industrial Emissions Directive. The locations of the sampling locations will be agreed with NRW, typically locations are north/south/east and west and at varying distances from the Installation.

Duplicate continuous emissions monitoring (CEM) systems will be installed. This will ensure that, in the event of a failure in the duty system, continuous monitoring of emissions to air will continue using the stand-by system.

All CEM systems that will be installed at the Installation to monitor emissions to air from the discharge stack will be certified under the EA’s MCERTS scheme for the appropriate measurement ranges and will meet the requirements of the quality assurance standard BS EN 14181:2004 Stationary source emissions - Quality assurance of automated measuring systems.

The CEM systems will be provided with an uninterruptable power supply (“UPS”) so that they will be able to continue monitoring the emissions to air from the discharge stack in the event of a power interruption to the plant.

All stack monitoring data is recorded at the Installation and NRW are able to request copies of all the data at any time, or indeed visit the Installation without any prior notice. In addition all Continuous Emissions Monitoring Data must be submitted to NRW at a frequency as determined within the Environmental Permit (usually quarterly). This information is then published on NRW’s public register.

Hitachi Zosen Inova (“HZI”) would be the Engineering, procurement, and construction (“EPC”) contractor. The Installation will be operated by a special purpose vehicle (“SPV”) set up following financial close, whereby HZI would operate the installation on behalf of Broad Energy Wales Limited.

The financing process to bring projects such as the Buttington Energy Recover Facility to life occurs in three main stages over the lifecycle of the project from the concept stage to when the facility becomes operational. It may also involve more than one provider of capital.

The first stage of capital provision towards the project is during the early phases of the project where the initial concept of situating an ERF at a given location requires additional investigative and administrative research work to prove the concept. The capital provided at this stage by project originators such as Broad Group enables surveys, technical investigations and legal documentation to be progressed to the point where the viability of the project is confirmed

Once viability of the project is confirmed, an additional capital commitment is provided by growth investors such as Low Carbon to undertake the many workstreams involved in materialising and developing the project. Examples of these workstreams include securing and maintaining grid connection, servicing land obligations and preparing the planning and permitting applications.

The final stage of the financing process is triggered once all the necessary regulatory, commercial and other contractual documentation is in place, with the project having been acknowledged and/or approved by all stakeholders. At this stage, capital is provided for the physical construction of the facility by institutional investors (such as infrastructure / pension funds). Given these institutional investors are large, long term asset holders, it is typical for them to acquire 100% of the project and hold on to it for the lifetime of the facility’s operations. This type of transaction typically follows a project financing structure such that the project and all of its associated rights and contracts are held within a standalone Special Purpose Vehicle (SPV), which is acquired by the investor with funds comprising both equity and debt capital. Once construction is complete, the daily operation of the facility may begin and the benefits of such a facility to all stakeholders may be realised.

It is anticipated that a local jobs fayre will be held with a view to recruiting, where possible, members of the locality. However, as is the same with any industry, if resource is not available, or not available to be upskilled, then jobs would have to be advertised further afield. It is hoped that such staff would settle in the area, thus contributing to the local economy.

The ERF will operate on a 24 hour a day, 7 days a week. This is necessary to ensure operational efficiency.

Incoming waste and deliveries of consumables, together with export of bottom ash could take place for up to 12 hours on weekdays (7am – 7pm) and 5 hours on Saturdays (7am-12pm).

The Buttington ERF would accept deliveries of waste for up to 12 hours on weekdays and 5 hours on Saturdays. Assuming equal numbers of HGV trips during each hour, there would be an average of 4 HGV arrivals and 4 HGV departures during each hour on a typical weekday.

HGVs will be routed to only use Main Trunk Roads. HZI will ensure that HGV’s etc follow a set route. This will be enforced via supply contracts with contractors/ suppliers etc. A vehicle routing scheme will be submitted to and approved by the LPA prior to any construction/operation of the ERF.

The transport impact assessment has been based on an average load of 15 tonnes.

Previously Broad had not selected a technology provider. Broad has now engaged with HZI to operate the plant and their design brings improved efficiencies that enable a similar sized plant to take more feedstock.

In accordance with the discussions / correspondence with the Welsh Government Office, AutoTrack swept path tests of the proposed Development access junction layout from the A458 have been undertaken using a max legal articulated HGV as the design vehicle to ensure all vehicle types can be accommodated. In reality the type of delivery vehicles will vary.

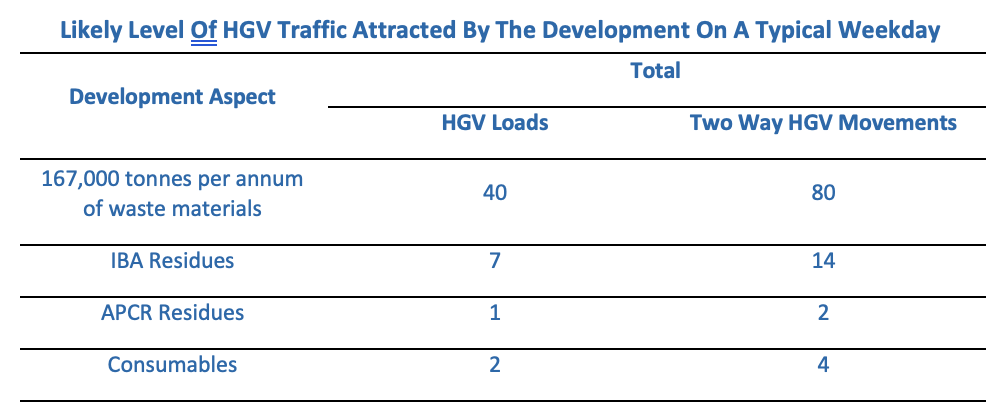

The new access is proposed approximately 170m north east of the existing access. The existing access is shown hatched on the drawing below, with the new access shown in blue. The full drawing may be found in Chapter 4, Technical Appendix 4.1 (Development Access Roads) - https://www.broadenergywales.co.uk/cd-content/uploads/files/Chapter-4-Description-of-the-Project.pdf - page 26 of the pdf.

We are aware that in the Chapter 12 of the ES and in the Heritage Statement by Orion Heritage the incorrect planning guidance is stated in a number of places. Where Circular 60/96 is mentioned in 12.2 of the ES and Page 3, 2.0 and 5.1 of the Orion Heritage report this should be replaced by Technical Advice Note (TAN) 24: The Historic Environment (May 2017). This provides the technical detail for the historic environment along with Planning Policy Wales.

Additional checks are in progress to ensure that that the information in this guidance has been properly cited and followed in the cultural heritage chapter of the ES and the Orion Heritage report.

Any amendments will be noted in the final version of both the Chapter and Supporting Statement.

We have also consulted with CADW and rigorously followed their guidance, and also the standards and protocols of the Chartered Institute for Archaeologists (CIfA) of which we are a Registered Organisation (RO) when preparing the Heritage Assessment and Heritage ES Chapter. Therefore, an objective assessment of the local area’s archaeological and heritage potential has been undertaken.

Broad Energy Wales only have control of the area within the planning boundary, however, as shown on the landscape master plan (please see Page 19 of the Drawings of the Development Download – additional areas of native broadleaved woodland is being planted around the quarry void.)

A list of waste that will be accepted at the installation, together with their European Waste Catalogue (“EWC”) codes, will be provided with the Environmental Permit Application. The majority of the waste will comprise wastes from waste management facilities, municipal wastes and wastes from construction and demolition sites, with an average net calorific value of 9.40MJ/Kg.

Waste will be delivered to the facility by road within covered vehicles. On entering the site, all waste delivery and operational vehicles will pass through an automated number plate recognition (“ANPR”) system. All waste delivery vehicles will be weighed on the In-Weighbridge on entering the site; the weighbridge - which is fully automated - will be linked to the ANPR and site Closed-Circuit Television (“CCTV”) systems. A manual ticketing system can also be deployed as a backup.

All waste delivered by an Authorised Vehicle will be accepted to the delivery point during the opening hours. However, waste will be rejected should the following circumstances arise:

· the load is in an Unauthorised Vehicle;

· the load is delivered with incomplete duty of care waste transfer note documentation,

· the load contains waste which would breach the conditions of the Environmental Permit for the site.

The mass of each load of waste will be categorised by EWC code and recorded. Where a vehicle is identified as containing, or suspected of containing, prohibited materials, the vehicle will be directed to the dedicated quarantine area for further inspection.

After weighing, authorised vehicles will be directed to one of the tipping bays in the Waste Reception Building by means of an electronic traffic light and barrier traffic management control system; each tipping bay is accessed by means of a fast action roller-shutter door which will be operated automatically on the approach of a vehicle. The roller-shutter door will close after the vehicle enters the tipping bay to ensure that all waste handling activities are undertaken within the confines of the building.

Following tipping of its waste, the tipping exit bay door will be opened and the vehicle will exit the site via the Out-Weighbridge, which is also fully automated and linked to the ANPR and site CCTV systems; this weighbridge will also be controlled via a traffic light and barrier system.

The incoming waste will be tipped directly into the waste bunker, which has a capacity approximately 4,100 tonnes, which equates up to approximately five to seven days storage capacity, this is presented due to density of waste variations.

If Prohibited Materials are observed in the load, these materials will either be isolated within the Waste Reception Area or moved to the Quarantine Area. Periodic random inspections on vehicles a will be undertaken and this will be carried out in the Quarantine Area. All such inspections will involve checking that the waste received is as described on the waste transfer note and is of a type permitted (i.e. as listed on the Installation’s environmental permit).

If the presence of a load containing Prohibited Materials prevents unloading or further deliveries, then the operator will implement the agreed contingency plan which details alternative destinations for the waste.

Yes – the full extent of the new planting can be found on the Landscape Master Plan which can be found https://www.broadenergywales.co.uk/cd-content/uploads/files/Drawings-for-the-Drawings.pdf at page 19.

It is anticipated that subject to chemical testing, the ash can be recycled, processed and reused within the construction industry.

We are not aware of any such process where any parameters are adjusted to take account of any climatic conditions.

It is anticipated that a local jobs fayre will be held with a view to recruiting, where possible, members of the locality. However, as is the same with any industry, if resource is not available, or not available to be upskilled, then jobs would have to be advertised further afield. It is hoped that such staff would settle in the area, thus contributing to the local economy.

From this question, we have found an error within Table 5 of the Market Report. The figure of 18ktpa for Wrexham LACW should be zero as the material is contracted to FCC at that time.

However, the corrected Table is as follows and has no effect on the totals used within the Report.

|

Authority |

Residual MSW ktpa |

Destination |

EFW Capacity ktpa |

Expiry Date |

Available LACW |

|||

|

2017 |

2025 |

2035 |

|

|

|

2025 |

2035 |

|

|

Wrexham |

38 |

36 |

36 |

Ferrybridge |

|

2032 |

0 |

36 |

|

Powys |

21 |

18 |

17 |

Various/Export |

|

2021 |

18 |

17 |

|

Ceredigion |

18 |

19 |

18 |

Various/Export |

|

2022 |

19 |

18 |

|

Shropshire |

72 |

70 |

69 |

Battlefields EFW |

96 |

2035 |

0 |

0 |

|

Telford and Wrekin |

45 |

39 |

39 |

2037 |

0 |

0 |

||

|

Sandwell |

86 |

85 |

87 |

Four Ashes EFW |

337 |

2037 |

0 |

0 |

|

Walsall |

71 |

59 |

58 |

2035 |

0 |

0 |

||

|

Staffordshire |

217 |

174 |

166 |

2035 |

0 |

0 |

||

|

Stoke |

78 |

76 |

75 |

Hanford EFW |

181 |

2025 |

0 |

75 |

|

Wolverhampton |

77 |

75 |

75 |

Wolverhampton EFW |

109 |

2023 |

0 |

0 |

|

Dudley |

91 |

78 |

76 |

Dudley EFW |

93 |

2023 |

0 |

0 |

|

Birmingham |

382 |

347 |

355 |

Tyseley EFW |

355 |

2024 |

0 |

0 |

|

North Wales Partnership |

125 |

121 |

117 |

Parc Adfer EFW |

190 |

2035 |

0 |

0 |

|

Hereford/Worcester |

216 |

179 |

175 |

Hartlebury EFW |

200 |

2030 |

0 |

0 |

|

Cheshire West/Chester |

67 |

64 |

61 |

Runcorn EFW |

|

2023 |

64 |

61 |

|

Cheshire East |

86 |

65 |

65 |

Ferrybridge |

|

2022 |

65 |

65 |

|

Total |

1692 |

1506 |

1490 |

|

1562 |

|

166 |

273 |

A conservation area is as defined under the provisions of the Planning (Listed Buildings and Conservation Areas) Act 1990 as amended by the Historic Environment (Wales) Act 2016 and subordinate legislation. There are over 500 such areas in Wales that have been designated by local planning authorities. The local planning authority determines “which parts of their area are areas of special architectural or historic interest the character or appearance of which is it desirable to preserve or enhance”. Such areas are then designated as conservation areas.

Cadw tasked the Royal Commission on the Ancient and Historical Monuments of Wales to create an inventory of historic battlefields in Wales. As part of this process the inventory adopted the following definition of a battlefield:

An area or location, terrestrial or marine, where a conflict occurred, involving military forces. All aspects of Wales’s past should be considered for the identification of historic battlefield sites, which may include traditional battles, sieges, invasions, skirmishes, ambushes, massacres and sites of civil unrest.

Over 700 battlefields have been identified, ranging from battles of the Roman period to outbreaks of civil unrest in the nineteenth century.

By generating energy from waste there is a reduction in greenhouse gas emissions due to the displacement of power generated by other power stations. Full details on how CO2 displacement was calculated can be found on Page 3-8 of https://www.broadenergywales.co.uk/cd-content/uploads/files/Chapter-3-Need-and-Alternatives.pdf. However, generating energy from the ERF will displace circa 40,000 tonnes per annum of CO2 from conventional power generation.

No – there are strict odour controls in place to ensure that there is no odour beyond the site boundary. The following mitigation measures will be implemented to reduce the risk of odour or vermin and scavengers arising from the Installation’s activities:

· all waste transfer, including loading and unloading will take place within the confines of the building;

· the reception of waste from delivery vehicles will take place through automatic fast-acting doors;

· once the waste materials are inside the building, all off-loading will take place within the building;

the Installation will be equipped with a sophisticated atmosphere control system - air collected by the atmosphere control system will be used as combustion air in the combustion plant chamber;

· all elements of the atmosphere control system will be incorporated into the Installation’s planned preventative maintenance (“PPM”) system;

· housekeeping, both externally and internally, will be of a high standard; the PPM system at the Installation will incorporate procedures for housekeeping, supported by the production of housekeeping schedules; and

· daily visual and olfactory assessments will be undertaken at the Installation.

The ERF will operate on a 24 hour a day, 7 days a week. This is necessary to ensure operational efficiency.

Incoming waste and deliveries of consumables, together with export of bottom ash could take place for up to 12 hours on weekdays (7am – 7pm) and 5 hours on Saturdays (7am-12pm).

The distance will vary, however, will generally be around a 2 hour travel time. The Broad Group are currently working with a number of transport companies who are using cleaner alternative fuels as a replacement to traditional diesel to transport waste material, it is intended that these will be used in the short term whilst keeping a close eye on developing electric and hydrogen technologies. Once these become commercially available there is potential for these to be used to transport all material in and out of the proposed facility.

Further to discussion with Powys Council Council’s Environmental Health Officer (“EHO”) and following a site visit to a similar Installation in Kidderminster it was confirmed by the EHO that “there were no unpleasant odours detectable at the site boundary” and “a qualitative assessment [of odour] would be acceptable”. In accordance with the Institute of Air Quality Management (“IAQM”) Odour Guidance (2018) an estimation of the effect of odour has been undertaken considering the risk of odour exposure and receptor sensitivity.

The nearest sensitive receptor (Cefn Cottage) is 182m north of the Installation (downwind). Under calm conditions, odour would remain within the site boundary due to the nature of the quarry void, however, during turbulent conditions odour would be moved away from the Installation and would gradually dissipate. When considering the wind roses for the numerical weather prediction data the winds are generally from the south west, which is in keeping with local knowledge of the site where the wind in known to funnel up the valley. Thus the nearest downwind receptor Cefn Cottage, would have the most effective odour pathway, whilst all other receptors to the north and north east would have a less effective odour pathway. It is considered that due to the topography of the location of the Installation, i.e. it is situated within the quarry void, it would require turbulent conditions for any potential odour to be dispersed beyond the site boundary, consequently the pathway effectiveness is considered moderate. Receptors located upwind are considered to have an ineffective pathway.

The Installation has been designed in accordance with best available techniques (“BAT”) to ensure that there is no odour beyond the site boundary, consequently the magnitude of the odour release is considered to be small.

Therefore, impact descriptors contained within the IAQM Odour Guidance, for a moderately effective pathway, with a small odour potential, the risk of odour exposure at the nearest sensitive receptor is considered Negligible Risk.

The final step in the assessment is to consider the sensitivity of the receptors. The majority of the receptors in the vicinity of the site are considered high sensitivity receptors, as they are predominantly residential, receptors are considered to expect a high level of amenity and are expected to the present, if not continuously, but certainly for a large period of time.

Consequently, based on the negligible risk of odour exposure and the high receptor sensitivity, the likely magnitude of odour effect at the nearest sensitive receptor location is classed as having a negligible effect in accordance with the IAQM Odour Guidance.

Professional judgment is then used to determine if this is “significant” or “not significant”. This is based on a number of factors such as the Magnitude of Impact, Geographic Extent, Frequency, Duration etc. (all of which are defined in each of the relevant EIA Chapters). For odour, operations are undertaken within the confines of the waste reception hall. The waste reception hall will be kept under negative pressure with extracted air used as combustion air to destroy any odour causing compounds. Fast acting roller shutter doors will be installed to the waste reception hall and will remain closed when not in use. The mitigation is incorporated into the design of the building and the operational procedures. Consequently, it is considered that there will be no significant impact from the tipping or storage of waste.

Impacts to population and human health have been assessed in detail within specific Key Environmental Aspect (“KEA”) chapters e.g. Air Quality, Noise etc, of the Environmental Statement. The assessments undertaken within each KEA chapter all conclude that no significant environmental effects to population or human health will arise from the Development. The conclusions and mitigation measures related to human health impacts within each KEA chapter are reproduced in Chapter 15, Table 15-2. Please see page27 of https://www.broadenergywales.co.uk/cd-content/uploads/files/Chapter-15-Health-Impact.pdf which lists each specific effect and the mitigation.

A study undertaken by Cranfield University on Assessing the perception and reality of arguments against thermal waste treatment plants in terms of property prices (K.J.O Phillips et al)concluded that the perceived negative effect of the thermal processing of waste on local property values is negligible.

This study considered a number of Energy from Waste facilities in the UK which had been operational for at least 7 years. Property sales data within 5km of the sites was acquired and analised. The local property sale prices were compared before and after the facilities became operational. The study concluded “No significant negative effect was observed on property prices at any distance within 5 km from a modern operational incinerator. This indicated that the perceived negative effect of the thermal processing of waste on local property values is negligible”.

The CEMS is a predictive and preventative system and not reactive. It is directly linked to the waste feeding system, the combustion control system and the flu gas treatment system. This is important as it monitors emissions levels 24 hours per day and is able to predict trending in emissions levels and send controlling messaging to the facility systems to ensure that the waste feed, combustion and flu gas treatment control systems are adjusted in real time to ensure that emission levels are maintained within the permitted levels at all times.

Should the CEMS predict that it is not possible to rectify an emission trend through the adjustment of the waste feeding, combustion control and/or flu gas treatment system then the it has the capability of shutting down the facility in a safe and controlled manner.

The CEMS system is continuously monitored by the facility Control Room and will be compliant with the IED 2010/75 EU Directive and the requirements stated in the Environmental Permit.

An assessment of the waste arising within the Development catchment has been undertaken. The catchment area initially considered was generally defined as a 2 hour drive from the Development Site. However, given the rural nature of large parts of Powys, and west and south west Wales, it was considered that waste arising from these areas would in fact travel far further than a simple 2 hour drive time. Consequently, in addition to Powys, the catchment area considered included Welsh counties to the north (Isle of Anglesey, Gwynedd, Conwy, Denbighshire, Flintshire, Wrexham), and south west (Ceredigion).

Given the Development’s close proximity to the English Border, the 2-hour catchment area also included English Counties such as Herefordshire, Shropshire, Cheshire and other West Midlands Counties.

On the basis of the findings within the Market Report, it is envisaged that around 44% of waste will be generated within Wales and therefore around 56% will be generated within English Authorities.

The Buttington ERF would look to secure waste firstly for Wales, with any additional requirement for waste coming from England.

In the Policy Intervention scenario, we have assumed that the effect of the Courtauld Commitment is additional to the underlying 0.50%pa resource efficiency and so the impact has been modelled at 0.85%pa to 2025 and falling thereafter.

The Buttington facility is being developed on a merchant basis but recognises the significant market gap as set out in the application. It is envisaged that the facility will provide a treatment solution for uncontracted Powys and Ceredigion Councils household waste (MSW) totalling 39ktpa (Table 5 of the Report).

The remainder will consist of C & I waste generated within the catchment i.e. 128ktpa. The present assumption is that around 38ktpa of this C & I value is generated within Wales and the remaining C & I feedstock (90ktpa) generated within the English Local authorities within the 2 hour catchment.

Broad Group uses the industry recognised European Waste Classification (EWC) system for categorising waste types to be managed at the Buttington facility.

The stack is 70m heigh above the ground level. The base of the quarry will be generally brought to 90m AOD (above ordnance datum). Note: 0m AOD is generally the mean sea level, therefore 90m AOD refers to the ground level being 90 above the mean sea level. The stack will therefore be 160m AOD, however will be 70m tall or 70m above ground level.

Changes to the exit temperature are not undertaken. The stack has been designed at a height of 70m to ensure appropriate plume dispersion under all weather conditions modelled – i.e. 5 years of hourly sequential monitored meteorological data, and 2 years of site specific numerical weather prediction data supplied by the Met Office.

The met data used in the model was for Shawbury, and Numerical Weather Prediction (NWP) data based on the location of the stack coordinates (see Section 2.12. of Technical Appendix 6-1). Consequently, to answer this question, we will focus on the NWP data only as this met data is based on the conditions at the location of the ERF, and specifically 2019 as this gave the highest process contributions for the majority of pollutants.

A Capping inversion can occur at the top of the boundary layer. The dispersion model models these effects by including extra terms in the plume concentration algorithms to allow for the reflection of material below the boundary layer top. An inversion will always be present in convective and neutral conditions, but only present in stable conditions if there is a temperature jump at the boundary layer. From the 2019 NWP data, the temperature jump occurs 2701 times (approximately 31% of the time) within the 2019 data set, thus capping inversions will have been modelled for convective, neutral and stable conditions.

Within the boundary layer, temperature inversions are expected to occur in during stable conditions. Stable conditions within the boundary layer are indicted when the model calculated boundary layer depth divided by the Monon-Obukhov length is greater than 1. Using the 2019 NWP data as an example, this occurs 3423 times (approximately 39% of the time), and the boundary layer height varies from 50m to 1036m. Note within the 2018 met data expected temperature inversions were more frequent (circa 56% of the time, however, 2019 gave higher predicted ground level pollutant concentrations).

To demonstrate that the plume is able to penetrate the inversion, the dispersion modelling software is also able to plot the fraction of the plume that penetrates the inversion layer. For example, on the 3rd October 2019 at 7am, the model predicts stable conditions, and a boundary layer height of 50m. The fraction of the plume penetrating the inversion layer can then be plotted as follows.

This demonstrates that the whole plume penetrates the inversion. However, in this case, the height of the inversion is lower than the height of the stack. Consequently, a boundary height of 90m was also considered – i.e. a height 20m above the height of the stack.

On the 5th January at 7am the model predicts stable conditions, and a boundary layer height of 90m. Please note that as the height of the stack is 70m, the plume height must also be considered. As shown in the plume height graph, the plume will not actually reach the temperature inversion until it is around 100m from the stack.

The graph below, clearly shows that as the height of the plume reaches the inversion the plume penetrates the inversion rapidly.

Both graphs clearly demonstrate that the plume fully penetrates the inversions.

As described in previous questions, the temperature of the flue gas is constant, and therefore it would not be altered to take account of the weather.

Guidance from Natural Resources Wales states that for long term air quality standards, process contributions that are less than 1% of the air quality standard can be considered not significant. The air quality standard for nitrogen dioxide is 40µg/m3, consequently, concentrations below 0.4µg/m3 are considered not significant. This concentration is indicated by the blue line on the isopleth above. Therefore impacts beyond this line are considered not significant and no further assessment is required. For those areas within the 0.4µg/m3 contour, further assessment must be undertaken and the predicted environmental concentration considered, that is the process contribution plus the existing background. The background concentration of nitrogen dioxide used in the assessment is 18.87µg/m3, this was obtained from diffusion tube monitoring adjacent to Buttington Methodist Chapel. Therefore at the maximum point of impact the predicted environmental concentration is 19.755µg/m3, or 49% of the air quality standard. Based on the Institute of Air Quality Management Guidance (which is used when further assessment is needed) this impact is classed as having a negligible impact on air quality (see Section 2.22. of Technical Appendix 6-1 for further details on significance assessment).

In relation to the query relating to higher concentrations at Golfa Wood (assumed to be referring to Moel y Golfa SSSI), this is an ecological receptor, hence the air quality standards and pollutants assessed are different to those considered when assessing impact on human health. However, taking oxides of nitrogen as an example, the ground level concentration at Moel y Golfa SSSI is 0.181µg/m3 which is 0.6% of the critical level set for the protection of sensitive habitat sites which is therefore considered not significant.

Further to discussion with National Rail, they have confirmed that there is no connection or sidings alignment into the Buttington Brick Works. A new connection would be required.

As part of our transport studies, we have carried out an evaluation of the possible use of the rail network for transporting material in and out of the site in Buttington, unfortunately as material is not arising from one central location we would require to put in place a number of bulking up stations which is not a viable solution.

As part of this process we engaged directly with National Rail to look at the possibility of building a rail siding to support the movement of material to the site, unfortunately the outline proposals received by Network Rail meant that this solution was both commercially and operationally unviable.

As a result our studios have concluded in us discounting the possibility of using the national rail network for the movement of material in and out of the proposed facility in Buttington.

The Broad Group are currently working with a number of transport companies who are using cleaner alternative fuels as a replacement to traditional diesel to transport waste material, it is intended that these will be used in the short term whilst keeping a close eye on developing electric and hydrogen technologies. Once these become commercially available there is potential for these to be used to transport all material in and out of the proposed facility.

The waste that the ERF will be looking to treat is non-recyclable non hazardous residual waste. This is the type of waste that is for example, generated in in material recovery facilities (“MRF”). The purposed of an MRF is to remove all recyclable materials from the incoming waste stream, the residual waste is what is left. It is waste material that can not be re-used of recycled and is either sent to landfill sites or to energy recovery facilities such as that proposed.

The substation will be located within the Installation boundary, from where cabling will run underground to the base of the quarry void (circa 104m in length), prior to overhead cable (circa 74m in length) to the existing electricity pylon as shown on the drawing below. The substation is shown as the purple block. Underground cabling is the dashed purple line, above ground is solid purple. The nominal voltage is 33kV. No new pylons are proposed.

The Buttington ERF would be operational 24 hours a day. Deliveries of waste would be for up to 12 hours (7am-7pm) on weekdays and 5 hours (7am-12pm) on Saturdays.

Yes – however deliveries of waste restricted to weekdays and up to 5 hours (7am-12pm) on Saturdays.

A detailed air dispersion modelling report has been undertaken. The full report can be found as technical appendix 6-1 of the Environmental Statement. However, in summary, an assessment has been carried out to determine the local air quality impacts associated with the emissions from the proposed Buttington ERF from both the Installation and the associated vehicle emissions. In addition, a qualitative assessment of odour impact has been undertaken.

As a worst-case, emissions from the Installation’s stack have been assumed to be at the maximum emission limit values which represents a conservative assessment of the impact as the actual emissions from the Installation are likely to be significantly lower.

A detailed screening assessment confirmed that the optimum stack height for the Installation would be 70m.

Predicted maximum ground level concentration process contributions are within the short and long term air quality objectives and are assessed as not significant (less than 1% of the air quality standard / environmental assessment level) for most pollutants assessed. For those that are potentially significant, further screening has demonstrated that it is unlikely that any AQSs will be exceeded as a result of emissions from the proposed Installation at the maximum point of GLC or at any of the potentially significant human receptors.

For the sensitive habitat sites, it has again been demonstrated that the impact from the proposed Installation is unlikely to result in a breach of the relevant Critical Loads or Critical Levels or have a detrimental effect on local habitat sites.

An assessment of plume visibility was also undertaken, which concluded that visible plumes would only occur around 30% of the time, and for 95% of the time, any visible plumes would remain within the site boundary.

An assessment was also made of the impact of the proposed plant when operating under the abnormal conditions permitted under Article 46(6) of the Industrial Emissions Directive. The results of the assessment indicated that it would be unlikely that any AQSs would be exceeded under such abnormal operating conditions.

The impact of road traffic emissions associated with the Installation, in all phases of the development can also be classed as not significant.

The odour assessment also confirmed that the Installation will have a negligible effect on the nearest sensitive receptors.

In summary, therefore, it can be concluded that the proposed Buttington ERF will not have a significant impact on local air quality, human health or sensitive habitat sites, nor give rise to any significant odour impacts.

Where do you envisage imported workers being housed whilst working on the construction of the plant?

It is envisaged that where possible construction workers will be employed from the local area. Should additional accommodation be required, existing letting accommodation will be used.

As part of our transport studies, we have carried out an evaluation of the possible use of the rail network for transporting material in and out of the site in Buttington, unfortunately as material is not arising from one central location we would require to put in place a number of bulking up stations which is not a viable solution.

As part of this process we engaged directly with National Rail to look at the possibility of building a rail siding to support the movement of material to the site, unfortunately the outline proposals received by Network Rail meant that this solution was both commercially and operationally unviable.

As a result our studies have concluded in us discounting the possibility of using the national rail network for the movement of material in and out of the proposed facility in Buttington.

The Broad Group are currently working with a number of transport companies who are using cleaner alternative fuels as a replacement to traditional diesel to transport waste material, it is intended that these will be used in the short term whilst keeping a close eye on developing electric and hydrogen technologies. Once these become commercially available there is potential for these to be used to transport all material in and out of the proposed facility.

Two ‘drop-in’ events were delivered in July 2019, one in Middletown Village Hall and the other at Buttington Trewern Community Centre. A total of 39 visitors attended the events. Two ‘formal’ consultation responses were received and also key themes discussed during the ‘drop in’ sessions were used to inform the HIA.

The period of notice and perceived limited scope of notification was criticised by the local community during the engagement events. The Project Team accepted this and, in order to address this, it was decided to circulate information about the Proposed Development and provide further opportunity to comment by way of sponsoring the November edition of the “Border Gossip” which is circulated to the local communities around the Trewern Community Council area. Unfortunately, no further correspondence has been received following the November edition circulation.

Whilst only two formal responses to consultation have been received, key themes identified during discussions at the ‘drop-in’ events were noted and have been discussed in relation to the potential associated health and well-being impacts.

We sent out over 3,500 booklets and feedback forms to the wider area. We have also made the information available on our project website for download.

Also we would like to be advised if this incinerator does go ahead, are you going to buy our homes at the now market value and all the moving expenses and relocation expenses that we will incur, as we have had our property valued and if the incinerator was to go ahead we will lose as much as 30% of the market price, leaving us trapped in homes and unable to move?

A study undertaken by Cranfield University on Assessing the perception and reality of arguments against thermal waste treatment plants in terms of property prices (K.J.O Phillips et al) concluded that the perceived negative effect of the thermal processing of waste on local property values is negligible.

This study considered a number of Energy from Waste facilities in the UK which had been operational for at least 7 years. Property sales data within 5km of the sites was acquired and analysed. The local property sale prices were compared before and after the facilities became operational. The study concluded “No significant negative effect was observed on property prices at any distance within 5 km from a modern operational incinerator. This indicated that the perceived negative effect of the thermal processing of waste on local property values is negligible”.

Impacts to population and human health have been assessed in detail within specific Environmental Statement Chapters of the ES insofar as they are relevant to specific topics. The population and human health impact conclusions and mitigation contained within each assessment (Key Environmental Aspect) chapter are reproduced in Section 15.10 of Chapter 15 of the ES. Assessments undertaken within each Key Environmental Aspect chapter all conclude that no significant environmental effects to population or human health will arise from the Development.

In addition, the Heath Impact Assessment (Chapter 15 – Technical Appendix 15-1) cross references these topics and aims to assess impacts to human health from a wider perspective. In conclusion, in the short term, there are potential dust, noise and additional vehicle movements associated with the construction phase. However, mitigation measures and recommendations can be implemented to ensure that population health impacts are addressed and controlled and no significant effects arise.

The Health Impact Assessment has also identified there are potential positive health impacts which can be achieved in the long term, such as employment, educational and training opportunities. More local jobs would help improve living conditions, housing and ultimately health and well-being. Further meaningful engagement from the local communities may generate additional positive health benefits through community support projects and other requested support from the development, if achievable.

In all cases, the health impacts have been assessed in respect of vulnerable groups and the recommendations suggested contribute to achieving equity and reducing inequalities.

The bottom ash generated is classed as a non-hazardous waste. It is anticipated that subject to chemical testing, the ash can be recycled, processed and reused within the construction industry.

The proportion of non-British work force is a function of the location of the sources of the main equipment supply chain, and the time during the construction phase this is measured. For example during the first 12 to 18 months, the civil engineering works are carried out, this is predominantly a British work force as the Civil Engineering sub-contractor will be a British company. This then during the mechanical and process equipment erection, as we import specialist plant and materials from abroad (for example the Moving Grate, Hopper, Boiler, parts of the Flu Gas Cleaning systems etc) and the those suppliers bring their own specialist erection and commissioning teams to team to site. Typically during this time the numbers of staff on site increase, and the ratio of British to non-British work force rises to approximately 60/40 respectively.

The work force for this project will where possible be taken from local sources. The main exception being that where certain plant and equipment is not available locally, or indeed in Britain this will have to be sourced from offshore. This will mainly be from European based companies.

It is envisaged that where possible construction workers will be employed from the local area. Should additional accommodation be required, existing letting accommodation will be used.

In similar projects that HZI has executed there is significant value added over the construction phase and life of the project to the local economy. Whilst specialist plant and materials are sourced outside of the local economy (where these are not able to be sourced economically locally) the vast amount of material will be sourced locally or from the region. It makes not sense economically or environmentally to increase the travel distances or good mileage more than necessary. In addition there is a significant local spend benefit to the local economy from the workforce for amenity, accommodation and welfare spend out of working hours (eg food, leisure, accommodation etc).

The waste that the ERF will be looking to treat is non-recyclable non hazardous residual waste. This is the type of waste that is for example, generated in in material recovery facilities (“MRF”). The purposed of an MRF is to remove all recyclable materials from the incoming waste stream, the residual waste is what is left. It is waste material that can not be re-used or recycled and is either sent to landfill sites or to energy recovery facilities such as that proposed.

The facility has been designed with a significant flexibility to cope with a very wide range of calorific values, and this has been based upon significant experience of the UK waste market composition; HZI is currently building its 12th and 13th facility here in the UK, with a combined annual treatment capacity of over 3 Million tonnes. We do not envisage that the waste supplied to this facility will present any issues with regards to the compliant operation of it.

The projections within the report are based on the actual performances of each individual Local authority included within the catchment at the present time. In that way it reflects the actual circumstances within the existing marketplace. We have then conducted the sensitivity analysis so that it reflects the outcome if each sensitivity was realised.

Powys Councillors: Amanda Jenner, David Jones, Francesca Jump, Gillian Corfield, Graham Breeze, Linda Corfield, Lucy Roberts, Martin Weale, Phil Pritchard.

Shropshire Councillors: Edward Potter, Heather Kidd, Matt Lee, Nick Hignett, Roger Evans

Clwyd and Powys Archelogical Trust

Dan Stykuc (Powys County Council Environmental Health Officer)

Dr Alison Merry (Public Health Wales)

Ed Huckle (Public Health England)

Glyn Davies (MP)

Helen Jones (AM)

Joyce Watson (AM)

Neil Hamilton (AM)

North & Mid Wales Trunk Road Agent (Planning)

Natural Resources Wales (Planning)

Natural Resources Wales (Area Office)

Powys County Council Contaminated Land Officer (Anthony Bullen)

Robin Williams (North Wales Regional Planning)

Russell George (AM)

Trewern Community Council

Welsh Government (Planning)

Trewern School

The HIA area was based on covering a wide enough area to gather sufficient health and community information data to help inform the HIA. If the area is too small or too large, then the relevance of the data can be diluted in relation to the project / policy for which an HIA is being undertaken.

We were keeping a close watch on Government Guidelines with regard to Covid-19 and the ability to meet people indoors. We didn’t put a deadline in the booklet as we wanted to keep as much time available as possible for people to register whilst still allowing sufficient time to organise a consultation.

The deadline for consultation was announced on the website on the 1st October – at this point the consultation has been ongoing for nearly 3 weeks and we had had no-one register. We also notified Cllr Amanda Jenner of this closing date and it was also published on various other social media.

We distributed booklets within a 3-mile radius of the Buttington ERF site. Much of Welshpool was covered within this mail out and we have also made the information available on our project website for download. If there is anyone you know who would like a booklet, please let us know their address and we will post one out first class for you.

Should the development be granted planning permission, a liaison group would be established prior to the construction phase. Liaison groups typically include local residents, local councillors, representatives from Natural Resources Wales, local educational establishments.

It is envisaged that where possible construction workers will be employed from the local area. Should additional accommodation be required, existing letting accommodation will be used.

In similar projects that HZI has executed there is significant value added over the construction phase and life of the project to the local economy. Whilst specialist plant and materials are sourced outside of the local economy (where these are not able to be sourced economically locally) the vast amount of material will be sourced locally or from the region. It makes no sense economically or environmentally to increase the travel distances more than necessary. In addition, there is a significant local spend benefit to the local economy from the workforce for amenity, accommodation and welfare spend out of working hours (eg food, leisure, accommodation etc).

An assessment of the waste arising within the Development catchment has been undertaken. The catchment area initially considered was generally defined as a 2-hour drive from the Development Site. However, given the rural nature of large parts of Powys, and west and south west Wales, it was considered that waste arising from these areas would in fact travel far further than a simple 2-hour drive time. Consequently, in addition to Powys, the catchment area considered included Welsh counties to the north (Isle of Anglesey, Gwynedd, Conwy, Denbighshire, Flintshire, Wrexham), and south west (Ceredigion).

Given the Development’s close proximity to the English Border, the 2-hour catchment area also included English Counties such as Herefordshire, Shropshire, Cheshire and other West Midlands Counties.

On the basis of the findings within the Market Report, it is envisaged that around 44% of waste will be generated within Wales and therefore around 56% will be generated within English Authorities.

The Buttington ERF would look to secure waste firstly for Wales, with any additional requirement for waste coming from England.

The emissions from the transportation of waste have also been assessed and concluded that there is no significant change in levels of nitrogen dioxide (please see Technical Appendix 6-2 for full details).

Emails were sent to County Councillors, Local Councillors, Town Councillors, Community Councillors, the Local MP, Clwyd and Powys Archaeological Trust, Powys County Council, Public Health England, Welsh Assembly, Public Health Wales, Natural Resources Wales and Trewern Primary School.

We also made a website notification on My Welshpool and we submitted a press release to the County Times. Statutory notices were placed near the site.

This project has been ongoing for many years, however, the project was due to go to consultation in June 2020. It was delayed in the hope that issues with COVID-19 would have passed by September. However, that does no appear to be the case, with cases increasing.

There have been a number of studies which have been undertaken which are only valid for a period of 2 years therefore we have decided to press on.

We are currently in the pre-application phase of the Development of National Significance application. The Developments of National Significance (Procedure)(Wales) Order 216 (and amendments) lists what must be published - https://www.legislation.gov.uk/wsi/2016/55/article/8.

If you click on this link you will note that at article 8a states that notice must be given in the form of a site notice, in writing to owners and occupiers of adjacent land and publishment of the notice in a newspaper. In article 8b, information is only required to be published on a website.

Broad Energy Wales has gone beyond their statutory obligations by distributing booklets to over 3,500 addresses in the locality – much of Welshpool was covered. There are many other such developments which are proceeding at this time, and there is no obligation to pause planning applications in line with the DNS (PINS Wales) guidance. Broad Energy has sought to engage widely with the community, and has developed a number of channels for those who wish to engage with the proposals.

We distributed booklets within a 3-mile radius of the Buttington ERF site. Much of Welshpool was covered within this mail out and we have also made the information available on our project website for download. If there is anyone you know who would like a booklet, please let us know their address and we will post one out first class for you.

A noise survey has been undertaken and an acoustic barrier is only required during the construction phase at Brookfield Cottage.

The quarry base is currently not level. Some parts are at a level of 88.725m AOD. The floor level of the building will be brought up to 90m AOD to form a level platform for the development.

The Buttington Brickwork SSSI will be protected during the construction phase and will not be damaged by the construction of screening embankments and drainage. It will be fenced off and tool box talks given about its importance and the need to protect it.

A site visit with NRW and Hitachi Zosen Inova (“HZI”) execution team was planned for March 2020 to discuss any mitigation measures for the construction phase. Unfortunately due to COVID-19 travel restrictions, this visit has been postponed. This section of the Construction Environmental Management Plan will be updated accordingly following the meeting once any further mitigation measures for construction have been discussed and agreed.

The external lighting strategy may be found on Drawing 4052-ID-DR-1002 in Technical Appendix 4-2, together with the lighting calculations and risk assessment.

In summary:

- Lighting levels for each area have been designed in accordance with BSEN 12464-2 for outdoor work places;

- Additional localised lighting will be required for ladders and platforms;

- Lighting has been designed to be in keeping with a site in a rural location;

- luminaires have been selected to minimise the impact on bats;

- Mounting heights have been selected to minimise lighting impacts;

- External backlight shields have been provided where required to minimise back spill;

- External lighting will operate all night with the exception of the ERF access road and firewater storage areas; and

- All external lighting will have primary photocell control to ensure it is not operational during daylight hours.

The main stack will extend from within the main building envelope and will measure 70m in height and will be lit with Night Vision Goggle visible lighting (as requested by Welshpool Airport following consultation with Pilots).

Impacts to population and human health have been assessed in detail within specific Environmental Statement Chapters of the ES insofar as they are relevant to specific topics. The population and human health impact conclusions and mitigation contained within each assessment (Key Environmental Aspect) chapter are reproduced in Section 15.10 of Chapter 15 of the ES. Assessments undertaken within each Key Environmental Aspect chapter all conclude that no significant environmental effects to population or human health will arise from the Development.

In addition, the Heath Impact Assessment (Chapter 15 – Technical Appendix 15-1) cross references these topics and aims to assess impacts to human health from a wider perspective. In conclusion, in the short term, there are potential dust, noise and additional vehicle movements associated with the construction phase. However, mitigation measures and recommendations can be implemented to ensure that population health impacts are addressed and controlled and no significant effects arise.

The Health Impact Assessment has also identified there are potential positive health impacts which can be achieved in the long term, such as employment, educational and training opportunities. More local jobs would help improve living conditions, housing and ultimately health and well-being. Further meaningful engagement from the local communities may generate additional positive health benefits through community support projects and other requested support from the development, if achievable.

In all cases, the health impacts have been assessed in respect of vulnerable groups and the recommendations suggested contribute to achieving equity and reducing inequalities.

The air dispersion modelling has demonstrated that maximum ground level concentrations of particulate matter (PM10) are predicted to be 0.103µg/m3 at the point of maximum impact. This is 0.26% of the air quality standard.

Whilst Wales does undertake a significant amount of recycling, non-recyclable was is still being generated by household and commercial and industrial sources. Landfill space is running out with the only landfill in Powys having a lifespan of only 2 more years. Consequently, facilities like this will be needed to dispose of residual waste and also recover the energy contained within the waste.

Approximately 25% of the input waste is converted to bottom ash. This is a material that can be recycled, processed and reused within the construction industry.

The impact of emissions from the ERF has been assessed in detail in Technical Appendix 6-1. Buttington Trewern Primary School was included as a receptor within the assessment. This impact of emissions on the school was considered not significant for all air quality standards (i.e. less than 1% of the long term air quality standards, and less than 10% of the short term air quality standards).

In terms of traffic, the entrance to the school is located on a trunk road. The traffic assessment has demonstrated that there is no detriment impact on the local highway as a result of an additional 8 vehicle movements an hour.

As indicated within Table 5.8 of the Transport Assessment, which is contained at Technical Appendix 8-1 of the Environmental Statement, once operational the development is only expected to add moderate additional traffic levels to the A458. The Personal Injury Accident history within the agreed study area is examined within the Transport Assessment. However, it is considered that the moderate traffic levels associated with the development proposal would be unlikely to materially affect the PIA record of the local road network. In addition, it is considered that any deficiency in the surfacing of the A458 would be picked up as part of routine maintenance on the trunk road by the Highway Authority.

The plant will be operated by HZI. HZI Zosen AG (“HZI”) is a Swiss technology provider and a wholly owned subsidiary of Hitachi Zosen Corporation (“HZC”), a Japanese industrial services business with an average annual turnover of circa £2.65 Billion and a current net asset value of circa £800 Million.

HZI would be both the main technology supplier and operator of the ERF.

HZI is a global technology leader for energy and material recovery from MSW, refuse derived fuel (“RDF”) and organic waste. HZI acts as an engineering, procurement, and construction (“EPC”) contractor delivering complete turnkey plants, using its own proprietary technologies. HZI solutions are based on efficient and environmentally sound in-house technology, are thoroughly tested, can be flexibly adapted to user requirements, and cover the entire plant life cycle. HZI’s portfolio is rounded off with strong operation and maintenance (“O&M”) capabilities.

HZI’s customers range from experienced waste management companies, public utility companies, and municipalities to up-and-coming partners in new markets worldwide. HZI has developed innovative and reliable solutions for grate combustion, anaerobic digestion, flue gas treatment, and material and energy recovery.

HZI is the global leader in the design, procurement and construction of moving grate Energy from Waste facilities, with over 500 tried and tested Energy from Waste references worldwide including 11 in the UK and Ireland. They are currently constructing their 12th and 13th facilities in the UK.

HZI has an experienced and knowledgeable team of engineers and technicians of more than 500 based in Zurich. HZI adopt an integrated approach from first concept design, through to commissioning and operation, including long term major maintenance and overhaul services. For all the key components, HZI have developed in house proprietary technologies that are tried and tested in design, manufacturing, supply, installation and operation over many years and many projects worldwide.

Specific UK and Ireland experience includes the facilities shown in Table 1-1 of ES Chapter 1. These were completed or are under construction over the last 10 years providing a total waste processing capacity of circa 3.8 million tonnes per year.

HZI has an experienced and knowledgeable team of engineers and technicians of more than 300 based in Zurich. HZI adopt an integrated approach from first concept design, through to commissioning and operation, including long term major maintenance and overhaul services. For all the key components, HZI have developed in house proprietary technologies that are tried and tested in design, manufacturing, supply, installation and operation over many years and many projects.

Specific UK and Ireland experience includes the facilities shown in Table 1-1 of ES Chapter 1. These were completed or are under construction over the last 10 years providing a total waste processing capacity of circa 3.8 million tonnes per year.

The work force for this project will where possible be taken from local sources. The main exception being that where certain plant and equipment is not available locally, or indeed in Britain this will have to be sourced from offshore. This will mainly be from European based companies.

The proportion of non-British work force is a function of the location of the sources of the main equipment supply chain, and the time during the construction phase this is measured. For example during the first 12 to 18 months, the civil engineering works are carried out, this is predominantly a British work force as the Civil Engineering sub-contractor will be a British company. This then during the mechanical and process equipment erection, as we import specialist plant and materials from abroad (for example the Moving Grate, Hopper, Boiler, parts of the Flu Gas Cleaning systems etc) and the those suppliers bring their own specialist erection and commissioning teams to team to site. Typically during this time the numbers of staff on site increase, and the ratio of British to non-British work force rises to approximately 60/40 respectively.

We have assumed around 18% of total waste inputs will come from Powys County Council.

An assessment of the waste arising within the Development catchment has been undertaken. The catchment area initially considered was generally defined as a 2 hour drive from the Development Site. However, given the rural nature of large parts of Powys, and west and south west Wales, it was considered that waste arising from these areas would in fact travel far further than a simple 2 hour drive time. Consequently, in addition to Powys, the catchment area considered included Welsh counties to the north (Isle of Anglesey, Gwynedd, Conwy, Denbighshire, Flintshire, Wrexham), and south west (Ceredigion).

Given the Development’s close proximity to the English Border, the 2-hour catchment area also included English Counties such as Herefordshire, Shropshire, Cheshire and other West Midlands Counties.

On the basis of the findings within the Market Report, it is envisaged that around 44% of waste will be generated within Wales and therefore around 56% will be generated within English Authorities.

The Buttington ERF would look to secure waste firstly for Wales, with any additional requirement for waste coming from England.

Plants were considered which are either built, in construction, or that had discharged all of their planning permission conditions.

Plants were considered which are either built, in construction, or that had discharged all of their planning permission conditions. The planning consent for the Potters Welshpool facility has been considered as a ‘low possibility’ development within our modelling. The original permission, approved in 2014 only approved an outline scheme that did not provide any details of the technology, environmental compliance measures, building dimensions and operating parameters. This position remains as at October 2020 and therefore the scheme has not been included within our modelling which only included facilities that are either currently operational, in the commissioning phase (yet to be fully operational) or that a full planning permission has been granted including evidence of all appropriate conditions being approved.

Our projections extend to 2035 only as the potential variations in market conditions are considered somewhat less predictable at that stage. However, our modelling has included the effect of Wales achieving recycling targets well in excess of the very best performers within the EU, some which included highly developed collection systems that are unlikely to be achievable within the geography and population spread within Wales and England. It is worth noting that within Table 5: Residual LA Contract Status within the catchment, there are no existing contract that extend beyond 2037. That would suggest that around 1.49 million tonnes of additional waste could be available between 2037 and 2050 within the catchment of the Buttington facility – 9 times the facility capacity.

The plant will be CHP ready, which means that it will be capable of exporting heat to an end user should the need arise. It is anticipated that the ERF will be a catalyst to encourage other developments to take up the areas within the wider quarry that are zoned for employment use. It is hoped that these would be development such as large scale agriculture, data centres, warehousing, distribution or office accommodation. All of which would be able to use the heat.

As part of our transport studies, we have carried out an evaluation of the possible use of the rail network for transporting material in and out of the site in Buttington, unfortunately as material is not arising from one central location we would require to put in place a number of bulking up stations which is not a viable solution.

As part of this process we engaged directly with National Rail to look at the possibility of building a rail siding to support the movement of material to the site, unfortunately the outline proposals received by Network Rail meant that this solution was both commercially and operationally unviable.

As a result our studies have concluded in us discounting the possibility of using the national rail network for the movement of material in and out of the proposed facility in Buttington.

The Broad Group are currently working with a number of transport companies who are using cleaner alternative fuels as a replacement to traditional diesel to transport waste material, it is intended that these will be used in the short term whilst keeping a close eye on developing electric and hydrogen technologies. Once these become commercially available there is potential for these to be used to transport all material in and out of the proposed facility.

It is our intention that this facility is a facility for Powys and Wales. Waste arisings have been considered within a 2 hour drive from the Development Site. However, given the rural nature of large parts of Powys, and west and south west Wales, it was considered that waste arising from these areas would in fact travel far further than a simple 2 hour drive time. Consequently, in addition to Powys, the catchment area considered included Welsh counties to the north (Isle of Anglesey, Gwynedd, Conwy, Denbighshire, Flintshire, Wrexham), and south west (Ceredigion).

Given the Development’s close proximity to the English Border, the 2-hour catchment area also included English Counties such as Herefordshire, Shropshire, Cheshire and other West Midlands Counties.

The facility will be R1 compliant and will be designed to be CHP Ready as per the Environment Agency definition of such.

The met data used in the model was for Shawbury, and Numerical Weather Prediction (NWP) data based on the location of the stack coordinates (see Section 2.12. of Technical Appendix 6-1). Consequently, to answer this question, we will focus on the NWP data only as this met data is based on the conditions at the location of the ERF, and specifically 2019 as this gave the highest process contributions for the majority of pollutants.

A Capping inversion can occur at the top of the boundary layer. The dispersion model models these effects by including extra terms in the plume concentration algorithms to allow for the reflection of material below the boundary layer top. An inversion will always be present in convective and neutral conditions, but only present in stable conditions if there is a temperature jump at the boundary layer. From the 2019 NWP data, the temperature jump occurs 2701 times (approximately 31% of the time) within the 2019 data set, thus capping inversions will have been modelled for convective, neutral and stable conditions.

Within the boundary layer, temperature inversions are expected to occur in during stable conditions. Stable conditions within the boundary layer are indicted when the model calculated boundary layer depth divided by the Monon-Obukhov length is greater than 1. Using the 2019 NWP data as an example, this occurs 3423 times (approximately 39% of the time), and the boundary layer height varies from 50m to 1036m. Note within the 2018 met data expected temperature inversions were more frequent (circa 56% of the time, however, 2019 gave higher predicted ground level pollutant concentrations).

To demonstrate that the plume is able to penetrate the inversion, the dispersion modelling software is also able to plot the fraction of the plume that penetrates the inversion layer. For example, on the 3rd October 2019 at 7am, the model predicts stable conditions, and a boundary layer height of 50m. The fraction of the plume penetrating the inversion layer can then be plotted as follows.

This demonstrates that the whole plume penetrates the inversion. However, in this case, the height of the inversion is lower than the height of the stack. Consequently, a boundary height of 90m was also considered – i.e. a height 20m above the height of the stack.

On the 5th January at 7am the model predicts stable conditions, and a boundary layer height of 90m. Please note that as the height of the stack is 70m, the plume height must also be considered. As shown in the plume height graph, the plume will not actually reach the temperature inversion until it is around 100m from the stack.

The graph below, clearly shows that as the height of the plume reaches the inversion the plume penetrates the inversion rapidly.

Both graphs clearly demonstrate that the plume fully penetrates the inversions.

All the chapters are identified as “For Consultation” as this version of the documents are for the pre-application consultation phase. Any changes made to documents will be noted in an amendments list following the consultation.

Previously Broad had not selected a technology provider. Broad has now engaged with HZI to operate the plant and their design brings improved efficiencies that enable a similar sized plant to take more feedstock.

Approximately 25% of the input waste will be converted to incinerator bottom ash (IBA). IBA is a non hazardous material that can be recycled and re-used within the construction industry.

The Buttington ERF has been designed to accept up to 166,500 tonnes per year of non-hazardous, residual waste. In reality the plant will actually accept around 150,000 tonnes per annum. The difference in the figures is based on the difference between the maximum design capacity and what is operationally possible. The Buttington ERF has been designed to run 24 hours a day, 7 days a week at a maximum throughput of 18.95 tonnes per hour. Based on 8760 hours in a year, this would give a maximum throughput of 166,002 tonnes per annum (or 166,456.8 tonnes in a leap year). However, installations such as that proposed do not operate 8760 hours a year as there are always maintenance periods, hence most installations work on the basis of 7900 hours per year to give a throughput of 149,705 tonnes per annum.